Case: Capturing, analysing and addressing anomalies in production and other areas of activity

The challenge that needed to be solved

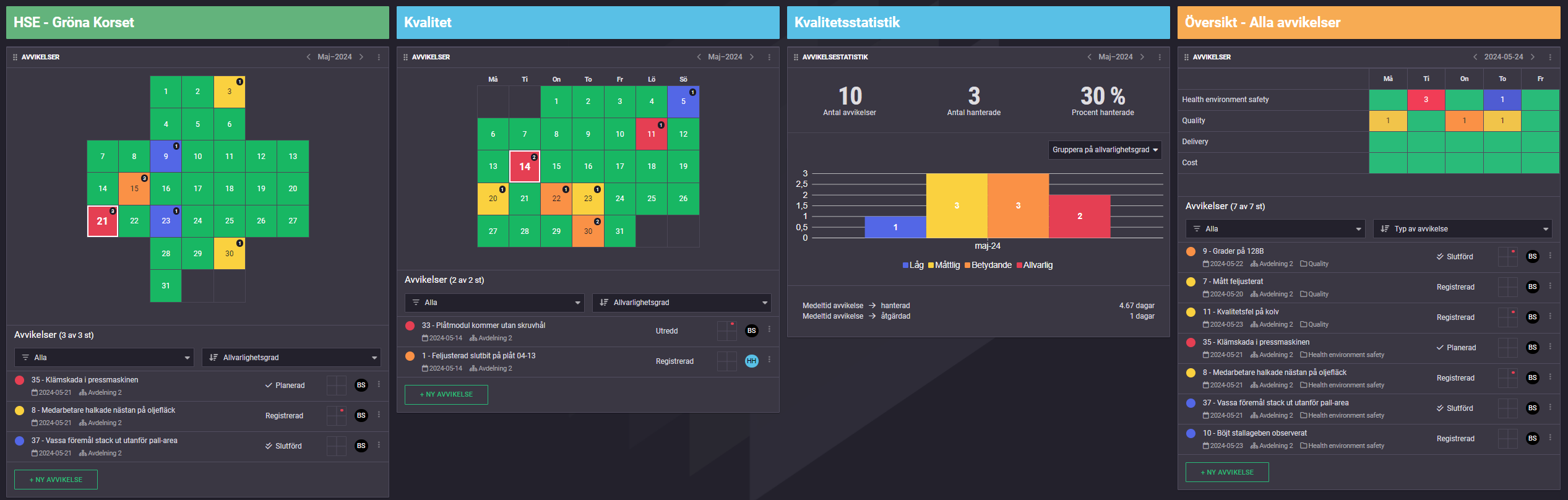

The challenge for Boards on Fire was to create a solution that effectively captures, analyses and addresses non-conformities in production and other operational areas. The goal was to address issues such as production disruptions, safety risks and quality deficiencies, with a particular focus on simplifying the registration process and enabling users to visualise deviations through different views, such as the Green Cross, Calendar view and Overview view.

Description of the solution and technology used

Boards on Fire developed a deviation module that covers the entire deviation management flow. It offers easy registration for operators and management, followed by a structured workflow to collect information in both text and image. The module enables risk assessment and prioritisation of deviations, root cause investigation using the ‘five whys’ method, and a systematic action planning process. This solution offers an efficient and transparent way of managing non-conformities and supports continuous improvement work.

Results and success factors

The implementation of the non-conformity module has led to increased efficiency through easy and fast registration of non-conformities, wherever they are detected. Customers have a clear overview of the status of each non-conformity, from identification to resolution. By linking non-conformities to improvement actions and enabling follow-up of results, the system has created better transparency and driven continuous improvement.

The impact of innovation on industry and society

The simple and quick process of registering deviations, which can be done in just 10 seconds via mobile, has enabled organisations to capture and manage deviations in real time. Through this module, companies get a complete picture of the entire flow from nonconformity to completed improvement, which can be implemented across a range of industries, not just manufacturing.

Future outlook and opportunities for further development

Boards on Fire continues to develop its product by releasing new features and improvements regularly. The company works closely with its customers to capture their needs and apply them to the product. Thanks to the flexibility and simplicity of the module, new areas of use have been identified, and Boards on Fire is now available in over 10 different industries.

Challenges during the development process and lessons learnt

During the development of the module, the company involved a reference group of four existing customers early on.These customers provided continuous feedback throughout the process.The biggest challenge was balancing the different customer requests, but this was successfully resolved.

All pilot customers were satisfied and are now actively using the module in live mode.